Gas Measurement (SOG)

Target Group

The Gas Measurement course is intended for employees who need to perform gas measurements and gas detection and interpret the measurement data. The measurements include explosive and toxic substances and oxygen.

Learning Objective

The employee learns in the course how to safely and professionally conduct and interpret gas measurements.

Theory

Toxic substances, poisoning, gases and vapors, effects on the body, limit values, TGG, dispersion factors, Vol.%/ppm/mg/m³, toxic substance measurement.

Fire and explosion, explosion area and limits, explosivity measurement.

Asphyxiation due to oxygen deficiency, effects of varying oxygen percentages, oxygen measurement.

Practice

Independently performing gas measurements:

Catalytic explosimeter.

Oxygen meter.

PID meter.

Chemical gas detection tubes.

Exam Language

The SOG exam is only available in Dutch.

Entry Requirements

The participant must be at least 18 years old.

Diploma: B-VCA, VOL-VCA, VIL-VCU, SCC-17, or SCC-18.

Recognition of ‘discoloration’ required.

Course Duration

Gas Measurement (ELCONY)

Target Group

The Gas Measurement course is intended for employees who need to perform gas measurements and gas detection and interpret the measurement data. The measurements include explosive and toxic substances and oxygen.

Learning Objective

The employee learns in the course how to safely and professionally conduct and interpret gas measurements.

Theory

Toxic substances, poisoning, gases and vapors, effects on the body, limit values, TGG, dispersion factors, Vol.%/ppm/mg/m³, toxic substance measurement.

Fire and explosion, explosion area and limits, explosivity measurement.

Asphyxiation due to oxygen deficiency, effects of varying oxygen percentages, oxygen measurement.

Practice

Independently performing gas measurements:

Catalytic explosimeter.

Oxygen meter.

PID meter.

Chemical gas detection tubes.

Entry Requirements

The participant must be at least 18 years old.

Course Duration

The participant must be at least 18 years old.

Diploma: B-VCA, VOL-VCA, VIL-VCU, SCC-17, or SCC-18.

Recognition of ‘discoloration’ required.

Diploma

According to the Occupational Health and Safety Act, Article 8 – Information and instruction.

Validity: 5 years.

Prices 1 day

€ 249.00 per person. For in-company training, a minimum of 6 participants is required.

Prices 2 days

€ 429.00 per person. For in-company training, a minimum of 6 participants is required.

Feel free to call us at +31(0)88-2200100 or send an email to info@elcony.com

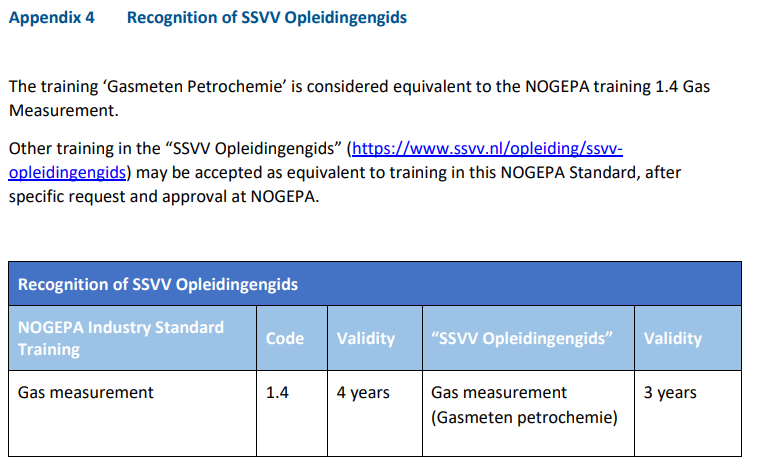

Gas Measurement (NOGEPA)

NOGEPA recognizes the SOG diploma ‘Gas Measurement’ from the SSVV.

SSVV does not recognize the NOGEPA diploma ‘Gas Measurement 1.4’.

Therefore, we always recommend choosing the SOG diploma ‘Gas Measurement’ from the SSVV.

Feel free to call us at +31(0)88-2200100 or send an email to info@elcony.com